This quick guide will help you keep resin prints on the build plate and off the FEP. If your prints are detaching from the supports, that is a different issue and we have an article on how to stop resin prints detaching from supports.

If your print keeps sticking to the FEP instead of the build plate, do not fret, the vast majority of time this can be solved by making a few simple changes. Beyond the common suggestions of releveling the bed and adjusting the FEP, here are a few things for you to do:

- Raise your base exposure time

- Lower your lift speed

- Lightly sand the build plate

- Add a raft

- Double check for defects

Raise your base exposure

Especially on older non-monochrome printers, the base/bottom/initial exposure can be increased to allow the resin to properly bond with the build plate. As a warning, setting the exposure exceptionally high can leave indentions in the FEP.

You can find resin print settings for most resins in our table, and you can help grow it by submitting settings.

Lower your lift speed

Lowering your lift speed, along with increasing the base exposure, are the easiest changes in your attempt to resolve the issue. A lower lift speed will lower the acceleration of the motor, thus decreasing the force on the bond between the resin and build plate.

Reduce the lift speed to a baseline such as 60 mm/min (1 mm/sec). Once you have successful prints, you can optimize and raise the lift speed.

Lightly sand the build plate

Lightly sanding the build plate will create tiny grooves that allow the resin to better bond with the build plate. Using a grit of 200-400 is often suggested, but you can opt for higher grits (400+) if concerned about permanent damage.

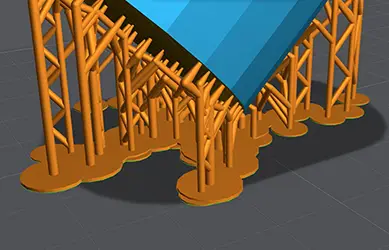

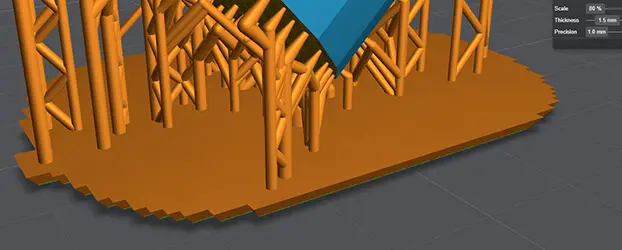

Add a raft

Individual support bases may use very little resin, but they do not provide a lot of surface area to bond with the build plate. Also, the bases can be difficult to remove from the plate, and they can often break or shatter into fragments when removing.

Rafts will securely bond to the build plate, and they are easy to remove after printing. Avoid excessively large rafts as they can create too much pulling force on the FEP film. If you do have large rafts, you can reduce their size in UVtools.

Double check for defects

Check the build plate for defects such as a warped bed. More common with prototypes and initial runs, the budget printer companies have sent out build plates with gaps up to ≈0.5mm. Even a gap as small as this can cause issues.

If your build plate has a gap or is warped, then you have the options of sanding the plate down or asking the manufacturer for a replacement build plate. Keep in mind that such replacements may take weeks as they are often shipped overseas.

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.