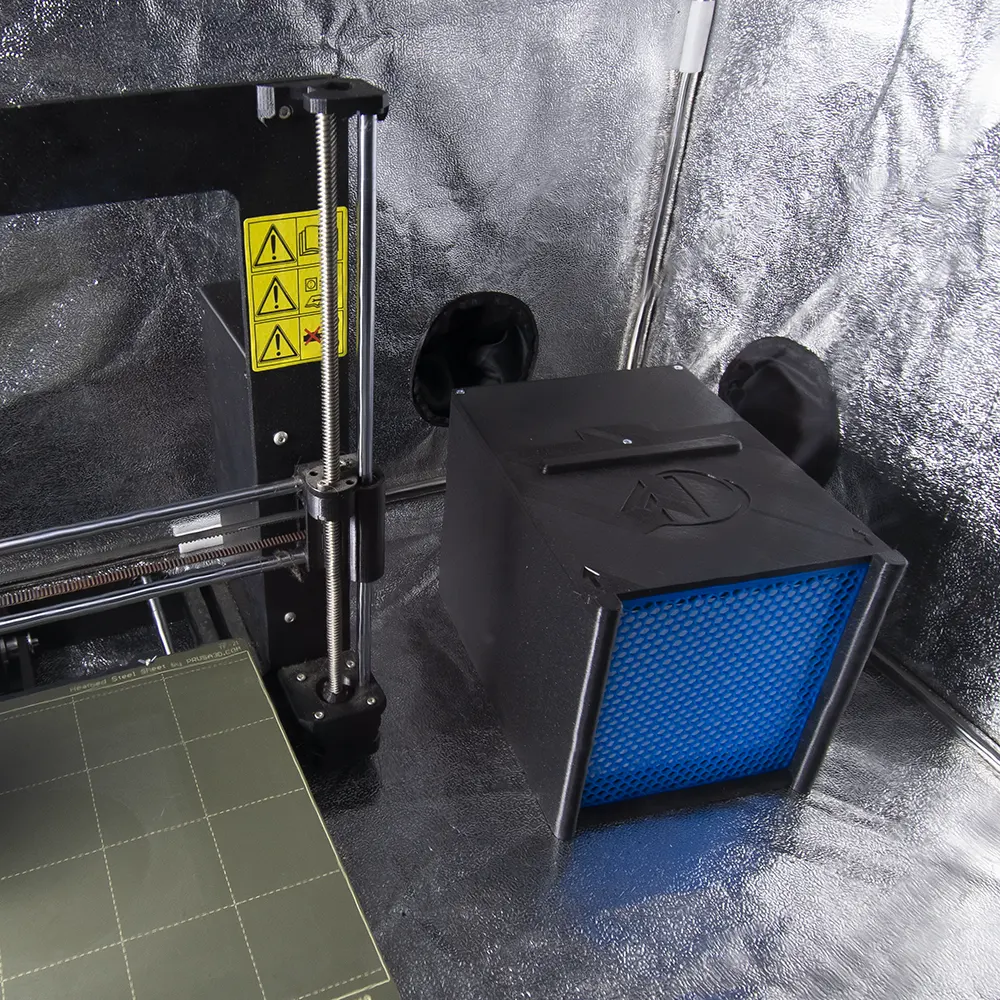

Promethean - 3D Printing Fume Extractor

- MERV 13 filter for capturing particulates

- Activated carbon for adsorbing VOCs

- Can be used as a small room air cleaner or fume extractor with provided the duct

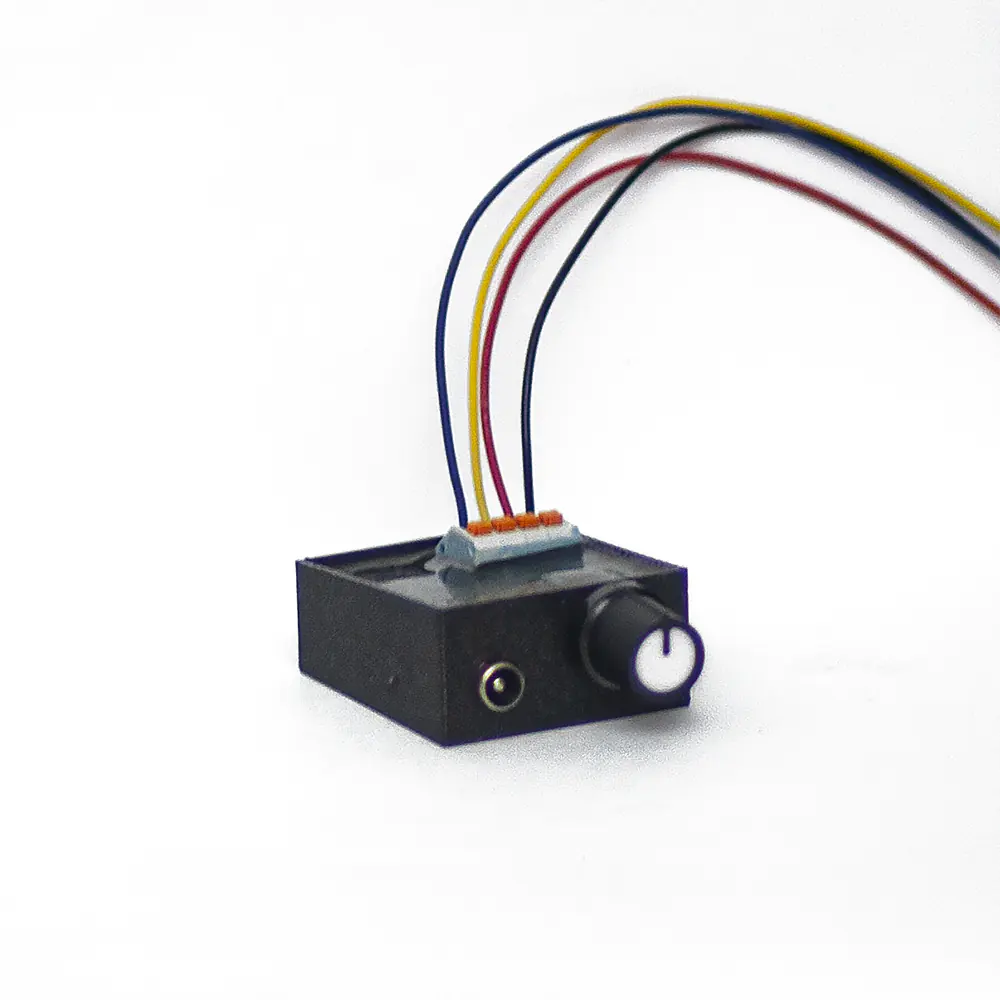

- PWM module for full speed control

- Made in the USA with US and foreign components

on Orders $100+