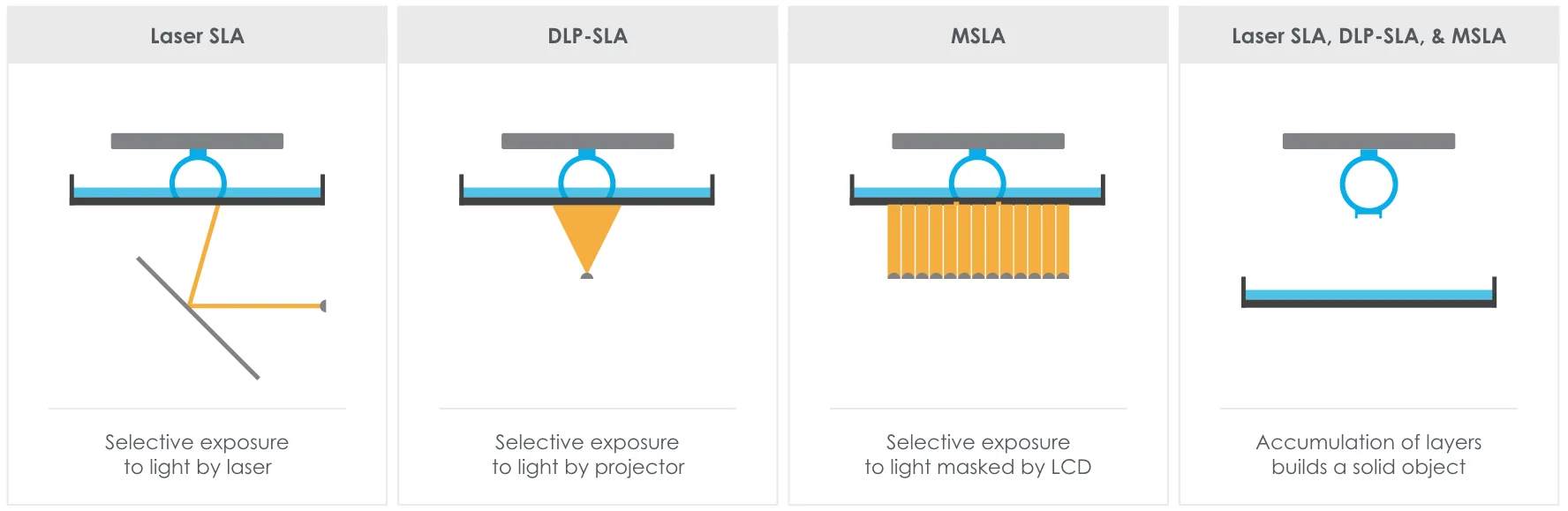

Masked Stereolithography (MSLA) is a modified form of SLA printing. SLA uses a laser to trace the layers, and it is often reserved for industrial use since it is expensive.

MSLA uses an ultraviolet (UV) LED array and a LCD screen to selectively cure an entire layer of resin in seconds. MSLA resin printers utilize widely available and affordable components, which makes the technology available to consumers.

Advantages of MSLA:

- Affordable printers and resin

- Good resolution - similar to SLA

- Smooth surface finish - no layer lines

- Fast printing speed - batch printing

- Variety of materials - flexible, durable, transparent, ceramic, and etc.

- Ability to print complex geometry

- Quiet printer operation

Disadvantages of MSLA:

- Safety - requires PPE and ventilation

- Small build volumes per price

- Extensive cleaning and post-curing process

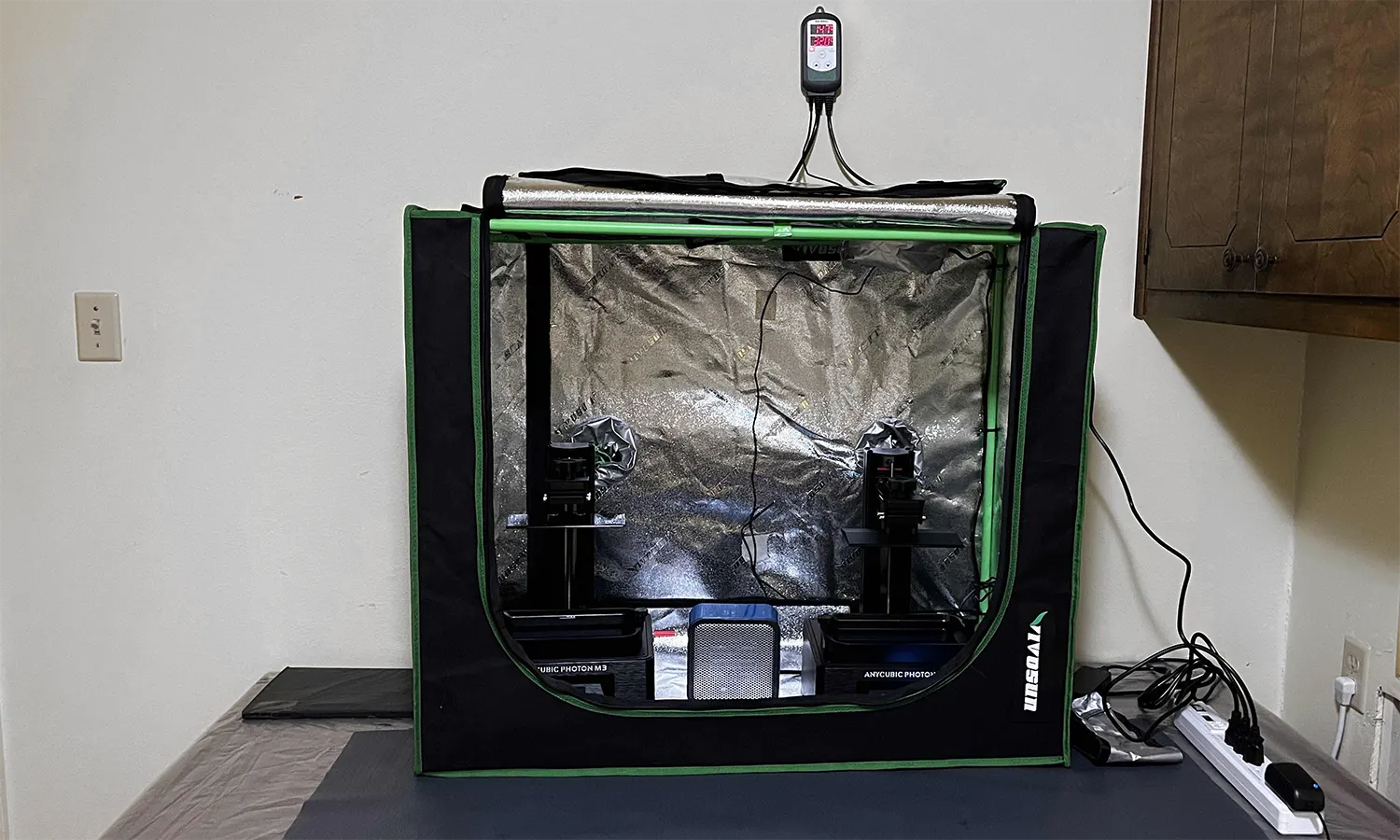

- Resin requires a heated or warm ambient temperature, usually 20-30°C

- XYZ shrinkage depending on resin and settings

- Warping can occur on large and improperly supported prints

How do MSLA resin printers work?

MSLA printers use a UV LED array underneath a LCD screen. The screen selectively turns pixels on and off, allowing UV light to cure the photopolymer resin in the vat. Budget resins often have cure times under 2.5 seconds, whereas the layer times for engineering resins can be 3 to 10 seconds.

When the layer has cured, the build plate lifts up, separating the print from the FEP or PFA film in the vat. The plate continues rising to a user-specified level then retracts down to start the next layer.

The FEP or PFA film will need to be replaced every few months or when indentions are made. The monochrome screens are degraded by the UV light, and their estimated lifespan is up to 2,000 printing hours. These should be considered a consumable.

How much do MSLA printers cost?

Small MSLA printers start at $200, medium-sized printers are $400-800, and large resin printers start at $1,100.

Budget resin is $25-40 per kilogram, and engineering resins are $40-150 per kilogram.

The remaining equipment can cost an additional $200-400. This includes cleaning equipment, an enclosure, ventilation, and heating.

What equipment do I need with a resin printer?

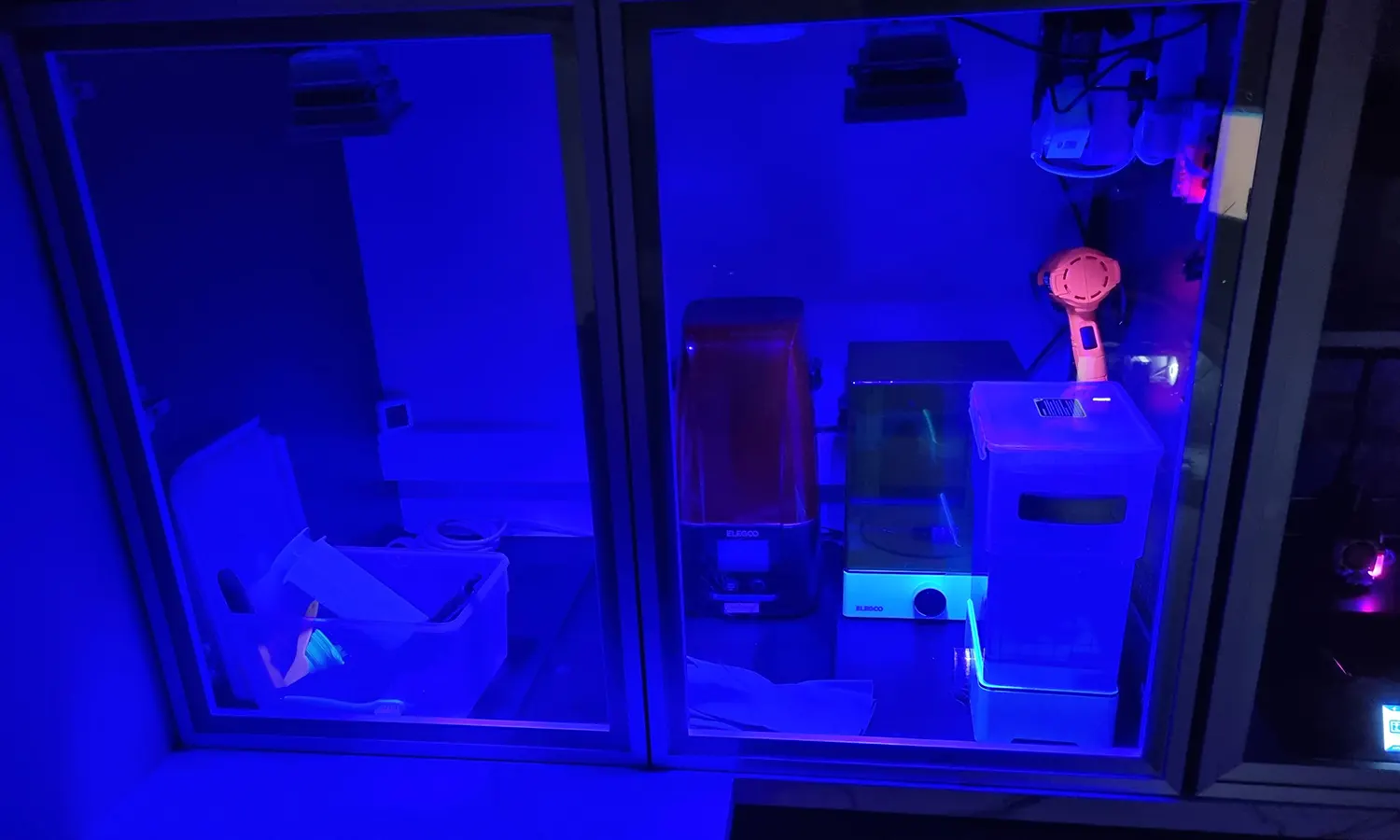

- Resin Printer ($200+) - Required

- STLs & Slicing Software (Free or Paid) - Required - Create models with CAD, download STLs from repositories, and slice your resin print.

- Resin ($25+) - Required

- Ultrasonic Cleaner ($60-300) - Optional - Good for cleaning complex geometry and cavities in prints.

- Wash and Cure ($100-250) - Optional - Automatic cleaning with IPA and post-curing in one machine.

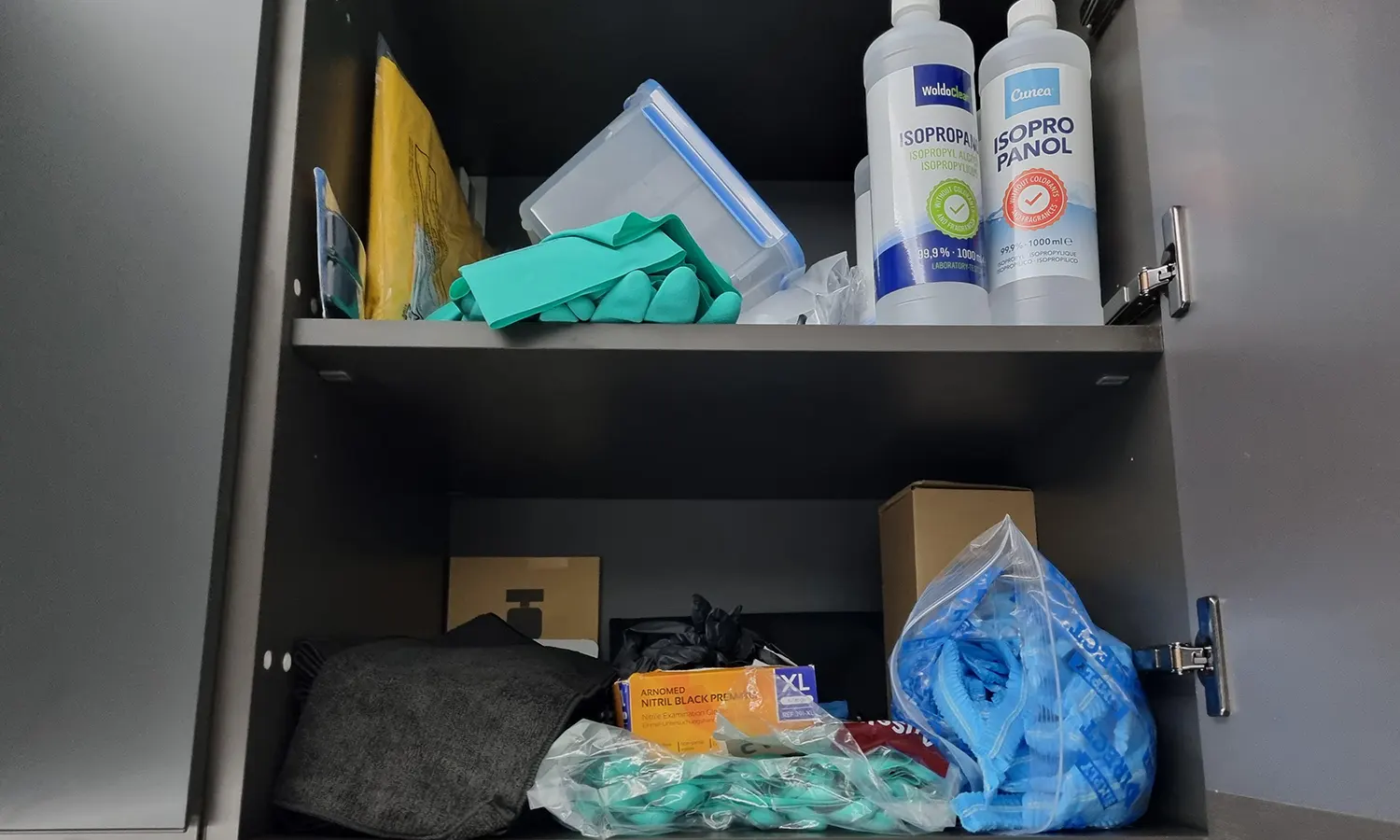

- IPA or Cleaner ($2-5) - Required - IPA is needed for most resin types.

- Nitrile Gloves ($15+) - Required - Disposable gloves provide extra dexterity but create additional waste. Thicker, reusable gloves can be cleaned after use and last dozens of sessions.

- Respirator ($20-40) - Required - A respirator with activated carbon should be worn when interacting with resin and cleaning prints. These can also be used for sanding and painting.

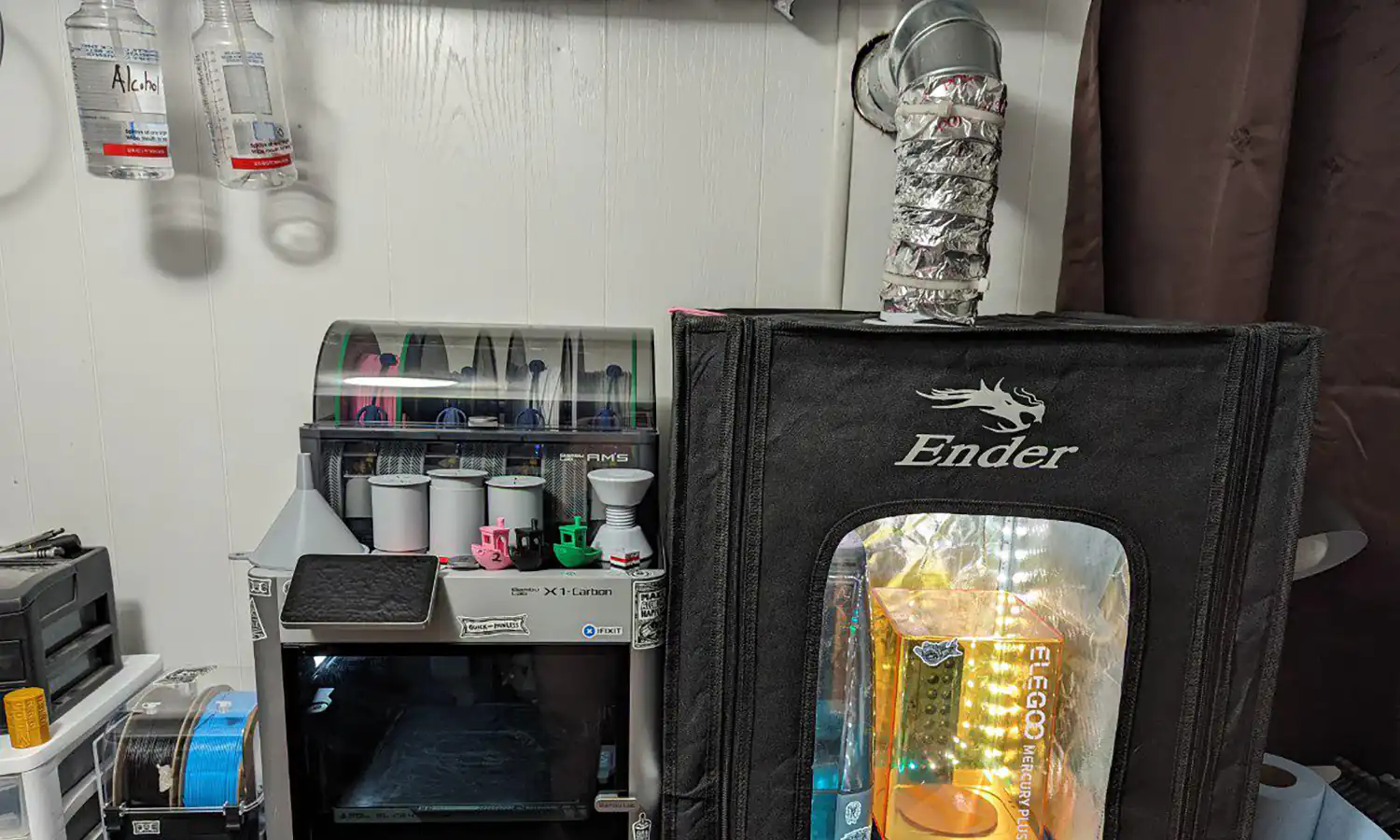

- Grow Tent ($60+) - Optional - An enclosure like a grow tent is generally required if you have the printer indoors. It enables easy and efficient venting. Also, an enclosure contains heat during the winter, especially if it is in a garage and doesn't need continuous venting.

- Heater + Controller ($15+) - Optional - A small ceramic heater and temperature controller are appropriate for most setups. Heat pads, space heaters, and sodium light bulbs can be used as a heat source.

- UV Lamp ($20) - Required - Portable UV LED array that can be used to post-cure prints, cure spills, cure resin in dirty IPA, and cure resin on reusable gloves after they are cleaned with IPA.

- Turntable ($8) - Optional - A turntable can be used with the UV lamp to rotate and evenly post-cure a print.

- Metal Funnel ($12) - Optional - A metal funnel reduces waste, and it is used for filtering debris out of the resin as it is poured back into the bottle.

- Flexible Plate ($15+) - Optional - Flexible plates can make removing prints easier, but they can cause failures on large prints that are printed directly to the build surface. The magnet adhesive will degrade over time.

- Silicone Mat ($8) - Optional - Silicone mats are a cheap way to keep resin off of your work table.

- Baster ($5) - Optional - Basters are recommended to remove resin from the vat. Typically, people would remove the vat and pour the resin out but this can drip resin on the screen, under the FEP film, and on your work space.

- Microfiber Cloths ($15) - Optional - Microfiber cloths can be used to clean the screen and FEP film.

- Soft Toothbrushes (<$10) - Optional - Soft toothbrushes, typically bamboo, can be used to clean resin out of crevices on a print.

- FEP or PFA Replacement ($5+) - Optional - Eventually, the FEP or PFA film will need to be replaced so it is a good idea to have some on hand.

- Screen Replacement ($50+) - Optional - Screens will need to be replaced months to years later, so we wouldn't necessarily recommend holding onto spares.

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.