Stereolithography (SLA) uses ultraviolet (UV) activated chemicals to manufacture highly detailed three-dimensional geometry. This technology has become accessible to small businesses and consumers, but the risks associated with the originally industrial process have not been eliminated.

Quick Facts About Photopolymer Resin:

- VOCs are heavier than air and sink to the floor but can be suspended by free convection

- SLA resin is detrimental to the environment and should be regarded as toxic waste

- SLA resin will kill marine life

- The exact health risks associated with SLA resin are not known due to proprietary formulas and the lack of research regarding safety

- Common input chemicals can cause allergies, acute/long-term organ damage, and reproductive toxicity

Common Resin Chemical Ingredients

These are some of the chemicals that are used in SLA resin, but this does not mean that they are in all resin. It is impossible to know what manufacturers are using, and even those with transparency maintain a level of proprietary discretion.

| Common Chemical Ingredients in Consumer Resin | ||

| Chemical | Potential Use | Warnings and Dangers |

| Isooctyl acrylate | pre-polymer | Respiratory Toxicity Aquatic Hazard Skin Irritant Eye Irritant |

| HDODA | pre-polymer | Skin Irritant Eye Irritant |

| HEMA | pre-polymer | Skin Irritant Eye Irritant |

| 1,1’-(Methylene-di-4,1-phenylene)bis[2-hydroxy-2-methyl-1-propanone] | photoinitiator | Organ Toxicity Aquatic Hazard |

| Hydroxycyclohexyl phenyl ketone | photoinitiator | Skin Irritant Eye Irritant |

| 2-Hydroxy-2-methylpropiophenone | photoinitiator | Aquatic Hazard Skin Irritant Eye Irritant |

| 2-Benzyl-2-dimethylamino-1-(4-morpholinophenyl)-1-butanone | photoinitiator | Respiratory Toxicity Reproductive Toxicity Aquatic Hazard Skin Irritant Eye Irritant |

| Azoisobutyronitrile | photoinitiator | Respiratory Toxicity Aquatic Hazard Fire Hazard |

| Epoxidized soybean oil | plasticizer | Skin Irritant |

| EGPEA | plasticizer | Respiratory Toxicity Reproductive Toxicity Aquatic Hazard Skin Irritant Eye Irritant |

| Polychloro copper phthalocyanine |

pigment | |

Guidelines for 3D Printing Resins

Setup Guidelines

- Operate the printers & store resin in a ventilated area

- Have a designated non-porous workspace (ie: glass table) or cover the workspace with trays, silicone mats, or plastic sheeting

- Wear a respirator, safety glasses, and protective clothing

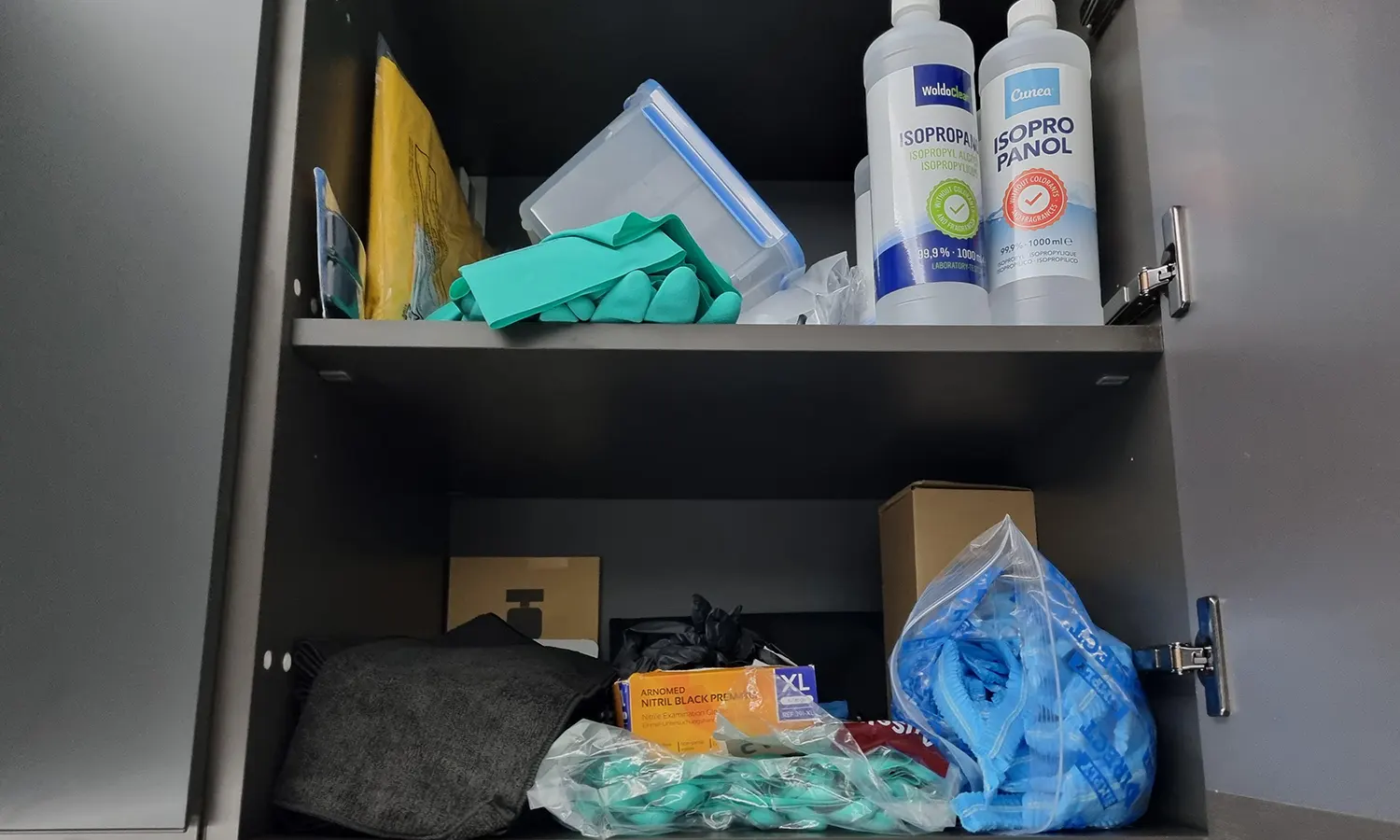

- Use only nitrile gloves

- If resin is spilled on skin wash off with soap and water - DO NOT use IPA or solvents

- Never pour resin or contaminated cleaners down a drain

- When possible, plan to clean prints before showers to remove unnoticed skin exposure

Printing Tips

- Remove wearables or jewelry before putting on gloves

- If resin was left in vat, stir then make sure no debris is present before printing

- Use a baster to transfer resin, or if pouring avoid drips onto the screen or bottom of the fep

- Print a 45° raft of ≈1.5mm thickness to peel prints off the bed with gloves instead of a scraper

- Store extra resin in a container that blocks light, or mix it in with a similar resin to minimize waste.

Cure unwanted liquid resin in a clear container before disposing as solid waste - To reuse contaminated cleaners, cure in a clear closed container then filter out the resin.

To dispose, allow the cleaner to evaporate & cure leftover resin before discarding - Clean tools that are foreign to the work area

- Throw away disposable gloves after curing the resin on them, either with a lamp or letting them sit in the sun - clean reusable gloves with cleaner/IPA and a UV light before removing

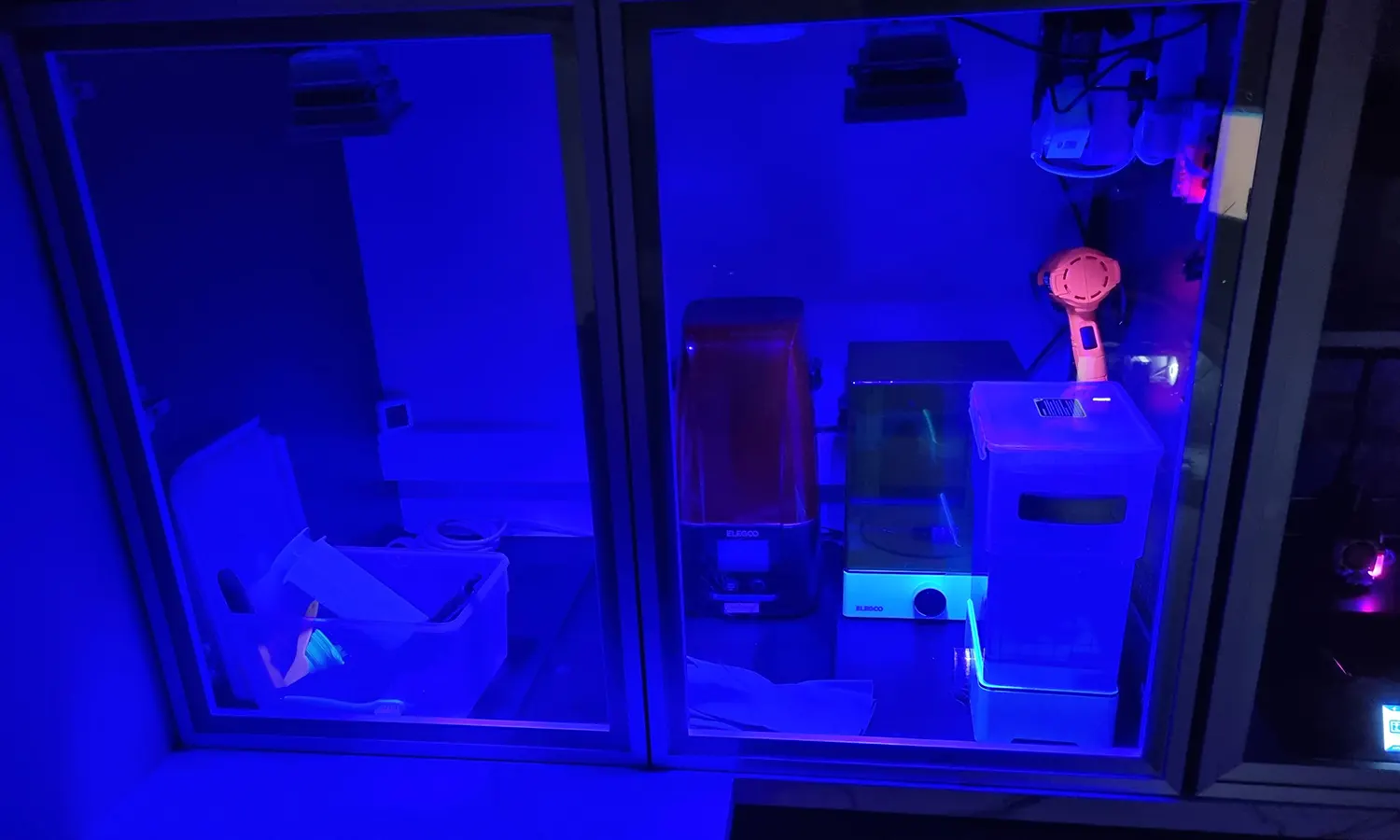

Interactive Resin Printer Setup

Double click or tap to go full screen, pan around 360°, and select the outlined items to learn more.Community Resin Printing Setups

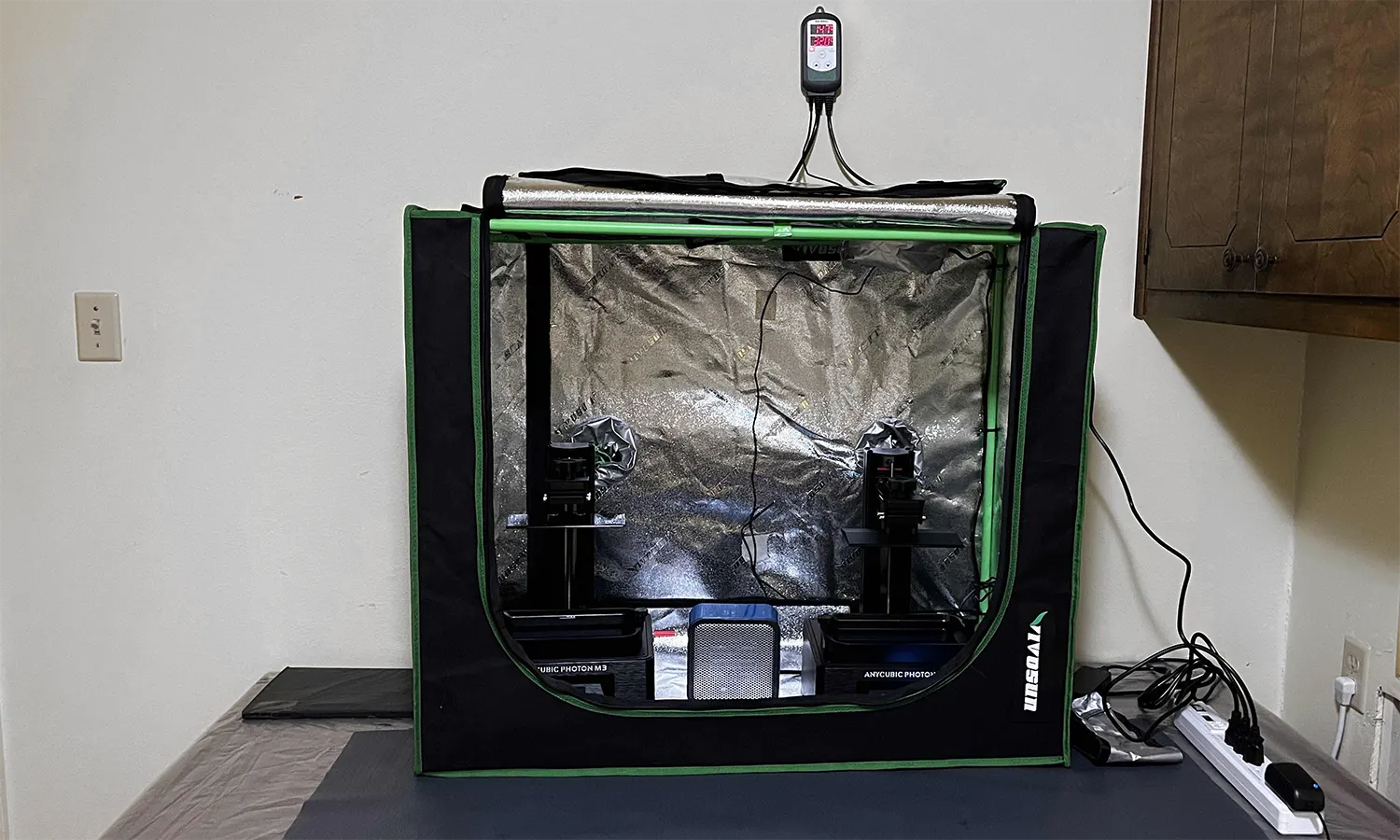

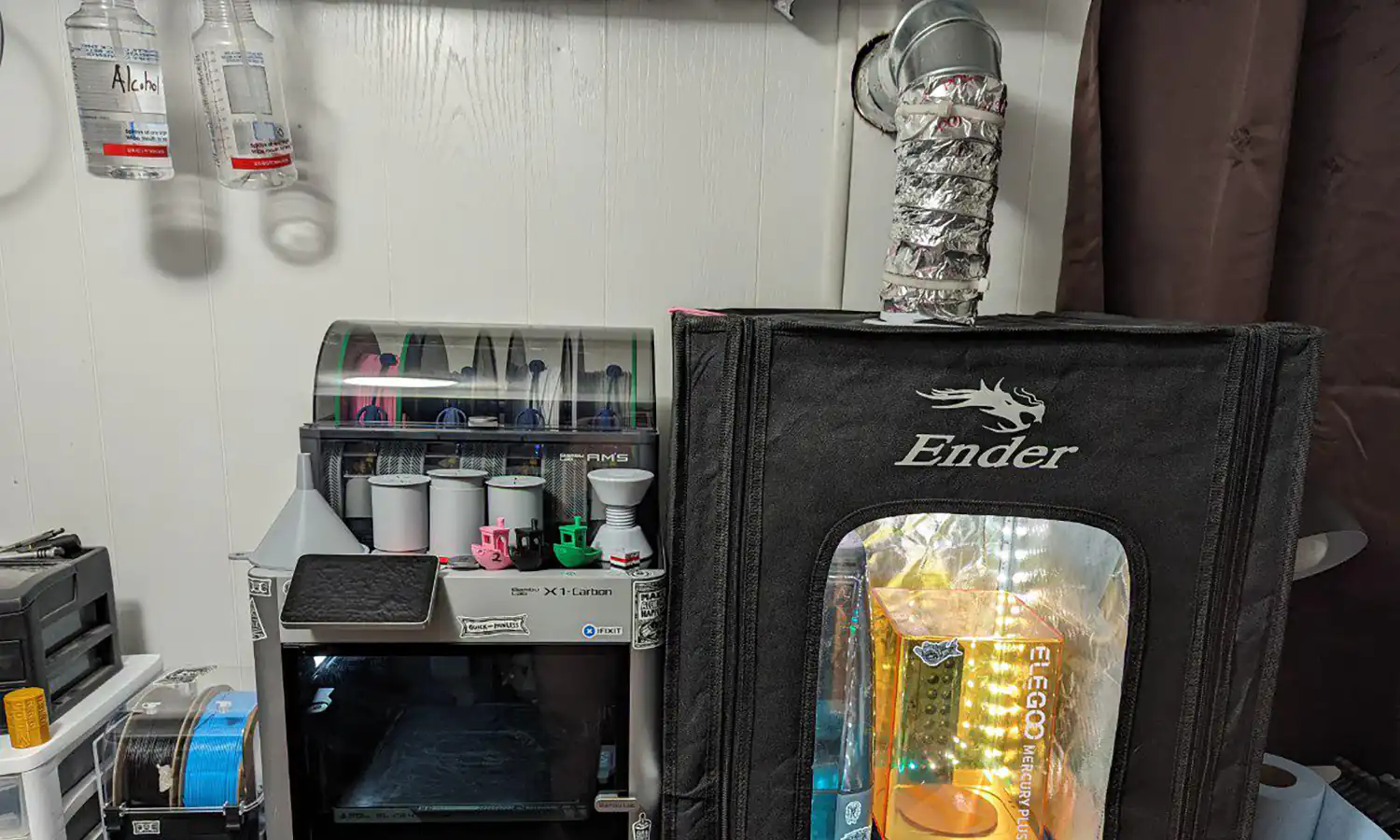

Email entries to [email protected] or on discord in the #showcase channel. We prefer the images to be landscape and at minimum 1,500x900px. Try to capture the essence of your setup in a single photo. If you have an exceptional setup that needs multiple photos, we'll use multiple slots or create a small slideshow.

Printers FAQ

The two main differences in resin printers are the screen type and size.

Monochrome LCD (mono) should be chosen over RGB/color screens due to: increased screen life (≈x4 longer), shorter layer cure times (≈2 seconds instead of ≈10), and reduction to energy use.

After 2022, most resin printers are now monochrome, but some of the older models are floating in the market.

Elegoo, Anycubic, and Phrozen have the most popular small resin printers. Elegoo and Anycubic provide affordable medium-sized resin printers.

The temperature will affect the viscosity of the resin. Lower temperatures raises viscosity and required exposure times. Higher temperatures will lower viscosity and exposure times.

Generally, entry level resins are designed to print at ≈ 20°C.

Engineering resins will print at ≈ +25°C.

You can use heaters for your resin printer.

Monochrome screens can last up to 2,000 hours, and color LCD screens last up to 500 hours.

The three most obvious signs of a dying screen are:

1. Visual failure of a screen exposure test.

2. Dead pixels that create holes throughout an entire print.

3. A thin layer of resin curing across the part, supports, or vat.

Screen protectors will reduce the UV power reaching the resin so you will have to up your exposure time, but having one will prevent the screen from being damaged by resin spills.

As an alternative to a screen protector, you can use a baster to transfer resin so you never need to take the vat fully off.

Slicing FAQ

The three main slicers are Lychee, Chitubox, and PrusaSlicer. Lychee and Chitubox offer free and paid versions. Both offer support for many brands of printers, but the community and developers of Lychee are excellent for troubleshooting and general questions. This includes a dedicated discord the devs run. PrusaSlicer is open source but requires UVTools to convert the files.

Most cases of the print sticking to the FEP are solved by decreasing the lift speed, increasing the bottom/initial exposure time, or lightly sanding the build plate.

If you are printing hollow prints, make sure to insert drain/pressure-equalization holes.

This can be beneficial for specific models that don't need supports, but remember that the first few layers can have elephants foot. This can be mitigated by chamfering the model in CAD, shrinking the model in UVTools, or utilizing extended light-off delays.

The best method to ensure easy removal is to create a raft within the slicing software that has a ≈45° edge and is at least 1.5mm in thickness. This raft can easily be lifted with your finger while wearing disposable or reusable gloves.

Most resin prints should start with a few heavy supports on the first few layers of contact, ideally somewhere that is out of sight.

Medium supports should be used to start every other island and should be stair-stepped in multiple directions to provide rigidity.

Finally, go back and place a healthy amount of light supports between and around all medium supports.

Resin generally shrinks 1-5% depending on the type and manufacturer, and the printing process can overexpose the resin in undesirable ways.

The fastest way to combat this is by printing a prototype and compensating for issues in CAD. Make sure to keep your print settings and variables such as temperature as stable as possible.

Example: a 10mm hole in CAD prints as a 9.8mm hole - go into CAD and make this a 10.2mm hole.

Resin FAQ

Heat Deflection Temperature (HDT) is the temperature at which a test bar loaded to a bending stress of [typically 66 psi for plastics] deflects by 0.010 in (0.25 mm).

It is essentially the temperature at which the printed object will begin to drastically deform.

Glass Transition Temperature (Tg) is the temperature at which the object will turn into a viscous liquid or have a rubber consistency.

The short answer is no. There are some commercial resins that allow for short-term skin contact but none are food-safe. While food-safe epoxies exist, they are only safe if mixed and cured correctly They are not recommended for long-term storage due to leeching.

Your best bet is to create a silicone mold from your print, use ceramic resin to cast metal, or sand cast using a wax resin.

The resin can absolutely be left in the vat provided the acrylic cover is on. If the printer is enclosed and not subject to sunlight then this can be indefinite.

The primary issue with resin sitting idle, especially pigmented resins, is that it will need to be mixed before printing. This can be done in the vat, but externally stirring the resin ensures that it is mixed thoroughly and prevents the FEP from being damaged.

If you leave the resin in after prints, make sure to remove cured resin debris from the vat.

The vats typically have a lip on a corner which is designed to pour resin out, but this often results in unintended resin dripping.

Our recommended method is to use a baster! This transfers the vast majority of the resin without having to remove the vat and create a mess.

Extra resin can be mixed with other resins to minimize waste, but be sure to adjust exposure times as needed.

Unwanted resin should be placed outside in a clear container for several days or until the resin is fully cured. This can then be disposed of as normal solid waste. Never pour anything down a drain or into the ground.

You can mix 10-20% of a flexible resin with 80-90% of a budget or ABS-like type to create prints that 'give' but are still easy to print.

Safety FAQ

Ideally, the resin printer should be outside the residence (ie: garage, shed, balcony) to prevent long-term exposure to fumes. An indoor alternative is to have the resin printer enclosed and vented out a window. The ideal indoor room would be low-traffic, sealed, and separated. This ventilation is your primary defense.

A secondary defense is air filtration. While activated carbon is not perfect, it provides a substantial reduction of pollutants.

If you need inspiration, we documented the transformation of a detached room for resin printing. This article include community resin setups.

Determine the level of risk you are willing to tolerate.

Since some of the chemicals that go into resin can cause reproductive harm, it is highly recommended that pregnant women are not exposed to resin at all.

Make sure that any printer can placed outside the residence.

Read the prior question for more information.

Immediately remove the contaminant with an item such as paper towels.

Wash the area with water and soap as soon as possible.

Do Not use a solvent such as IPA to remove the resin from your skin.

Do Not pour resin down any drain, regardless of the circumstance.

Resin is toxic to marine life and certainly does no favors to the public water supply.

Place unwanted resin in a clear container outside and allow it to fully cure.

The cured resin can be discarded as solid waste.

Nitrile rubber is a prominent type of chemical-resistant glove.

Typically, these gloves are disposable, thin, and one can often go through several pair in a day. This can create a lot of unnecessary waste in terms of cost and environmental impact.

A good solution is to use thicker nitrile gloves (cotton lined gloves are easier to take off) that can be used for many sessions. However, a good method of cleaning the gloves must be established.

Such a method could include removing resin with a solvent and paper towels then curing resin on the gloves using a UV lamp.

The best method to avoid fumes is to place the printer outside of your residence. If the printer must reside inside, ventilation and filtration should be used.

Absolutely! Not all chemicals will have a detectable odor, and the ones that do can leave you desensitized after a prolonged period.

The printer should only be placed on a surface that you are willing to subject to solvents or discard. A flat non-porous material that will not be degraded by solvents is ideal. The best example of this is a glass table since they are common and affordable.

A common practice is to place the printer within a disposable baking tray or on silicone mats.

Enclosing the printer has multiple benefits including:

1. Increases control over ventilation and filtration

2. Keeps the heat in during winter

3. Provides energy savings, versus heating the entire room

4. Blocks external UV light and allows for printing without the acrylic cover

5. Helps keep dust away from the printer

6. Contains any resin spills during printing

A grow tent is an easy and affordable enclosure to setup.

Dry sanding a resin print releases particulates that can enter your lungs.

The three best ways to prevent this is:

1. Work in a well ventilated area

2. Wear a respirator

3. Wet sand

The 60921 cartridge from 3M will protect against particulates and fumes during sanding and short-term exposure to resin printing. This type is affordable, can last several months, and should be regarded as an investment into your health.

Take Action

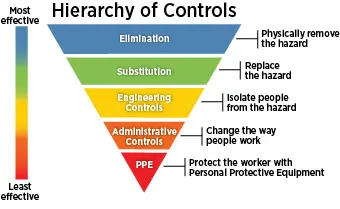

https://www.cdc.gov/niosh/topics/hierarchy/default.html

Sources

- https://www.sigmaaldrich.com/US/en/sds/aldrich/755885?sdslanguage=en

- https://www.sigmaaldrich.com/US/en/sds/aldrich/441090?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/2_2_-Azobis_2-methylpropionitrile#section=GHS-Classification

- https://www.sigmaaldrich.com/US/en/sds/aldrich/440167?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/3-Glycidoxypropyl_trimethoxysilane#section=Safety-and-Hazards

- https://www.sigmaaldrich.com/US/en/sds/aldrich/525464?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/2-Hydroxyethyl-methacrylate#section=GHS-Classification

- https://www.fishersci.com/shop/products/1-hydroxycyclohexyl-phenyl-ketone-98/AAL1137706

- https://pubchem.ncbi.nlm.nih.gov/compound/1-Hydroxycyclohexyl-phenyl-ketone#section=Safety-and-Hazards

- https://www.sigmaaldrich.com/US/en/sds/aldrich/405655?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/2-Hydroxy-2-methylpropiophenone#section=Safety-and-Hazards

- https://www.sigmaaldrich.com/US/en/sds/aldrich/408336?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/2-Phenoxyethyl-acrylate#section=Safety-and-Hazards

- https://www.sigmaaldrich.com/US/en/sds/aldrich/405647?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/86171#section=Safety-and-Hazards

- https://www.sigmaaldrich.com/US/en/sds/aldrich/246816?sdslanguage=en

- https://pubchem.ncbi.nlm.nih.gov/compound/1_6-Hexanediol-diacrylate#section=Safety-and-Hazards

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.