Resin and FDM printers emit Ultrafine Particles (UFPs) and a variety of VOCs while in operation. We can use ventilation and filtration to mitigate these emissions.

UFPs can be effectively captured using MERV 13-16 or HEPA 13 filters. VOCs are trickier and more expensive to capture at high efficiencies.

Enclosing the 3D printer and venting the fumes outdoors is an effective and affordable method to expel both UFPs and VOCs. The 3D printer should be placed outside the home whenever possible to mitigate long-term health risks.

Table of Contents

Placing 3D Printers Outside The Home

Garages and workshops are ideal spots for 3D printers

It is recommended to place resin printers outside the residence. This mitigates any long-term health risks associated with the resin chemicals off-gassing.

FDM printers using engineering filament like ABS, ASA, Nylon, or PC will be safest outdoors in a garage.

Venting Indoor 3D Printers

Ventilation required for resin printers and engineering filament

Resin and FDM printers using engineering filament inside your house should be placed in a separate and sealed room. Printing with PLA does not need ventilation, but using an air filter is recommended to capture the UFPs.

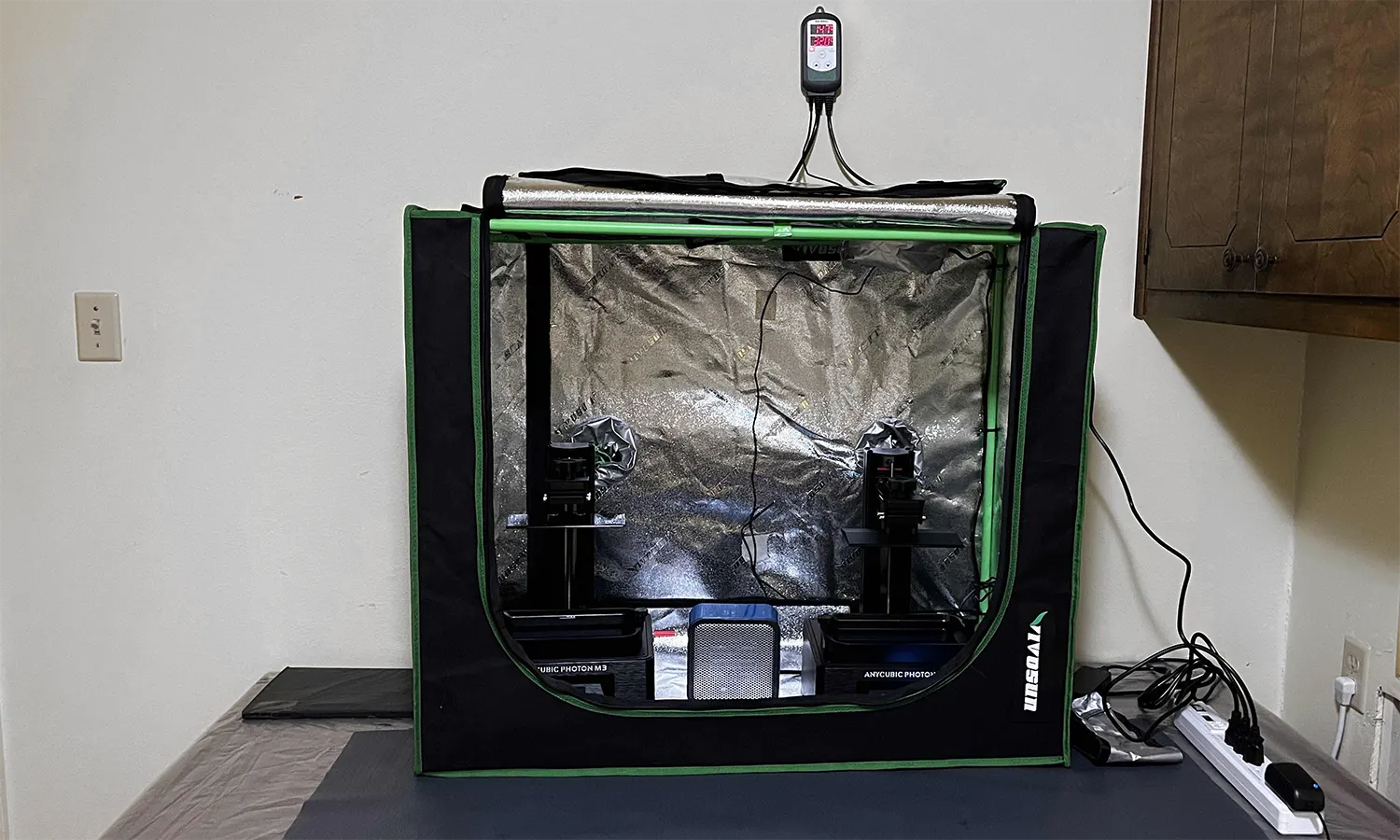

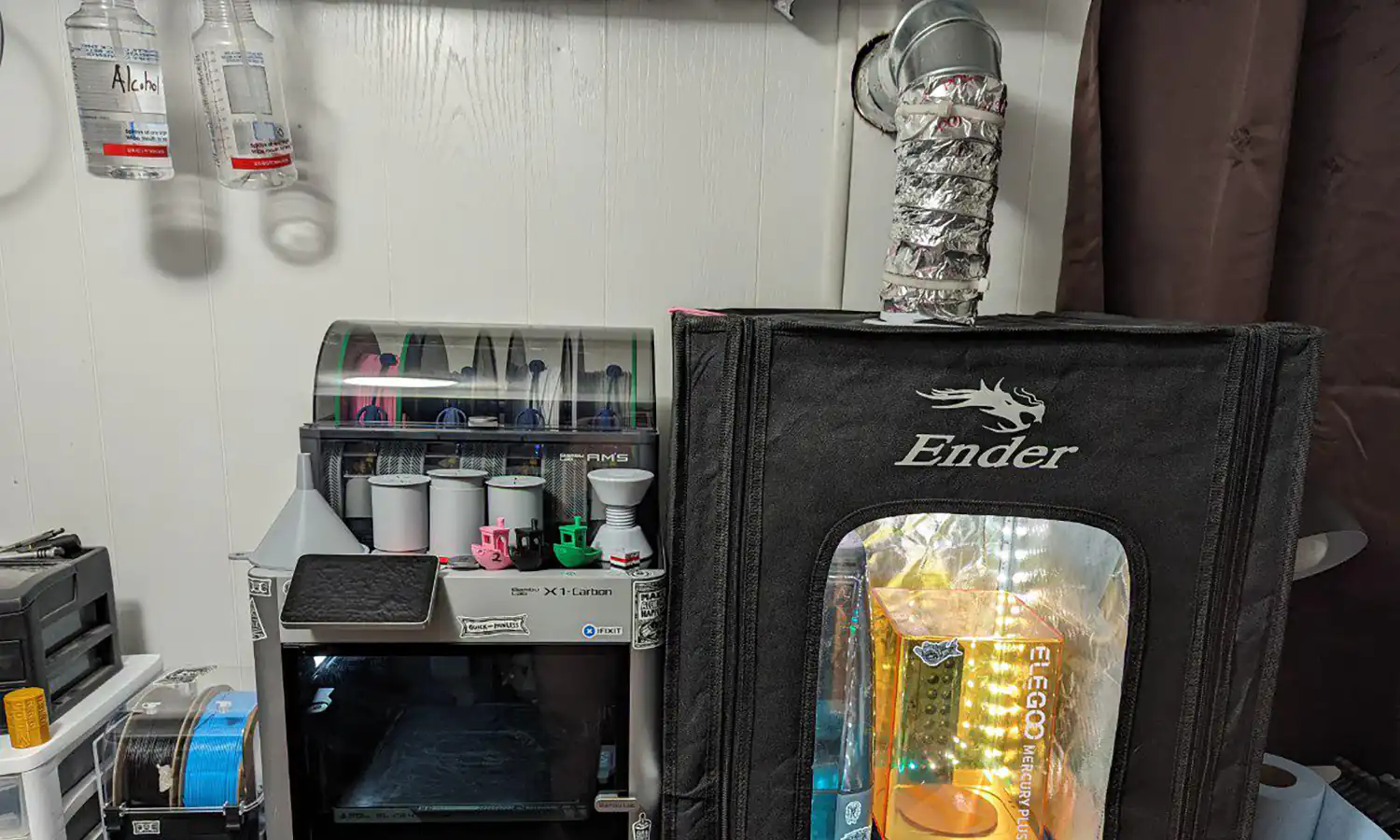

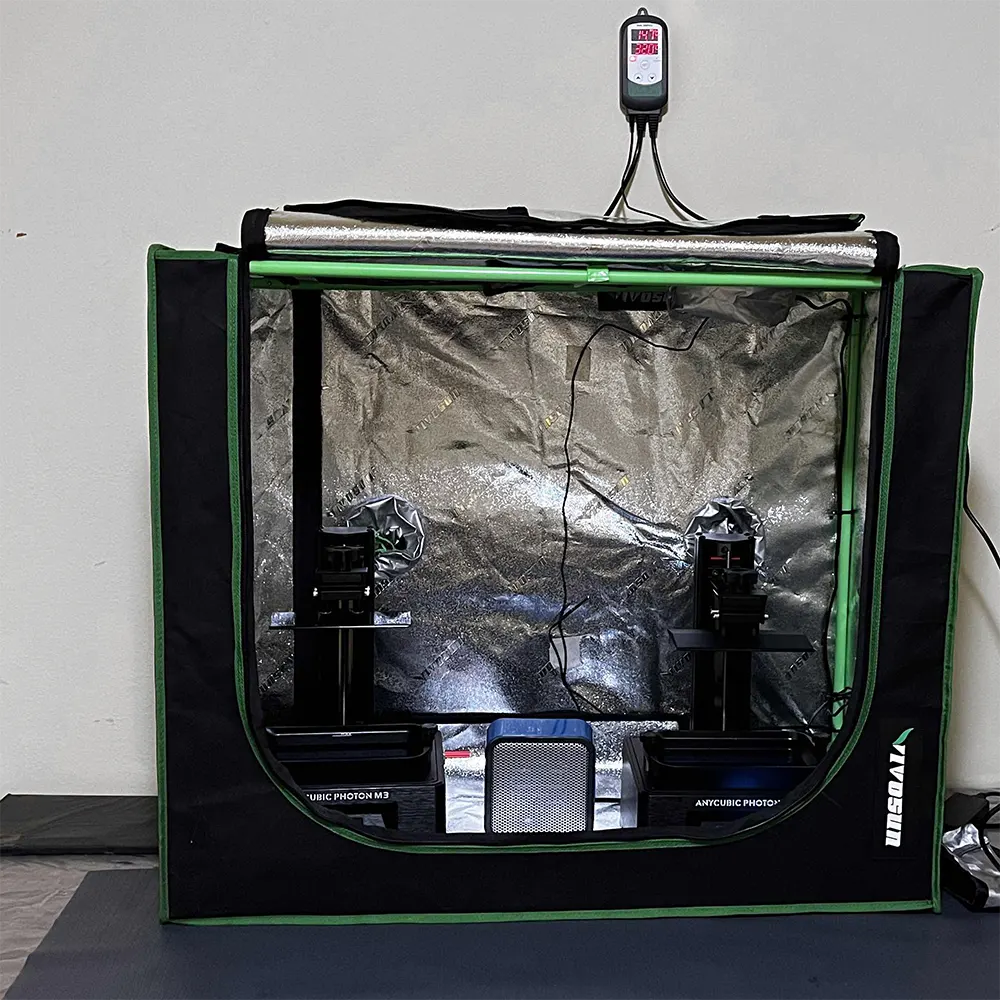

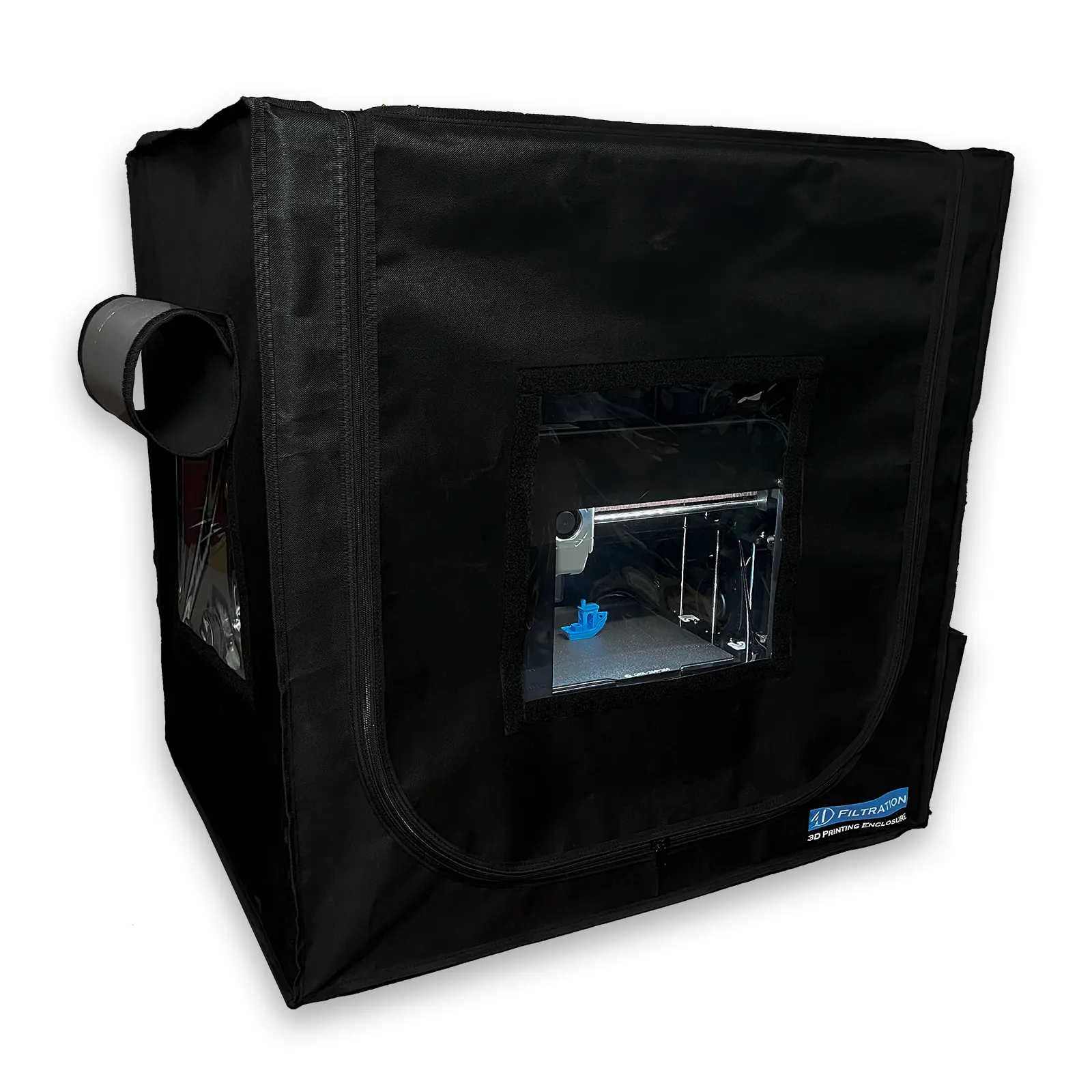

These FDM and resin printers should be placed in an enclosure like a grow tent. Flexible duct will connect your enclosure to a window adapter. You could drill a hole through the wall but that is not always practical. An inline fan will exhaust the 3D printer fumes outdoors.

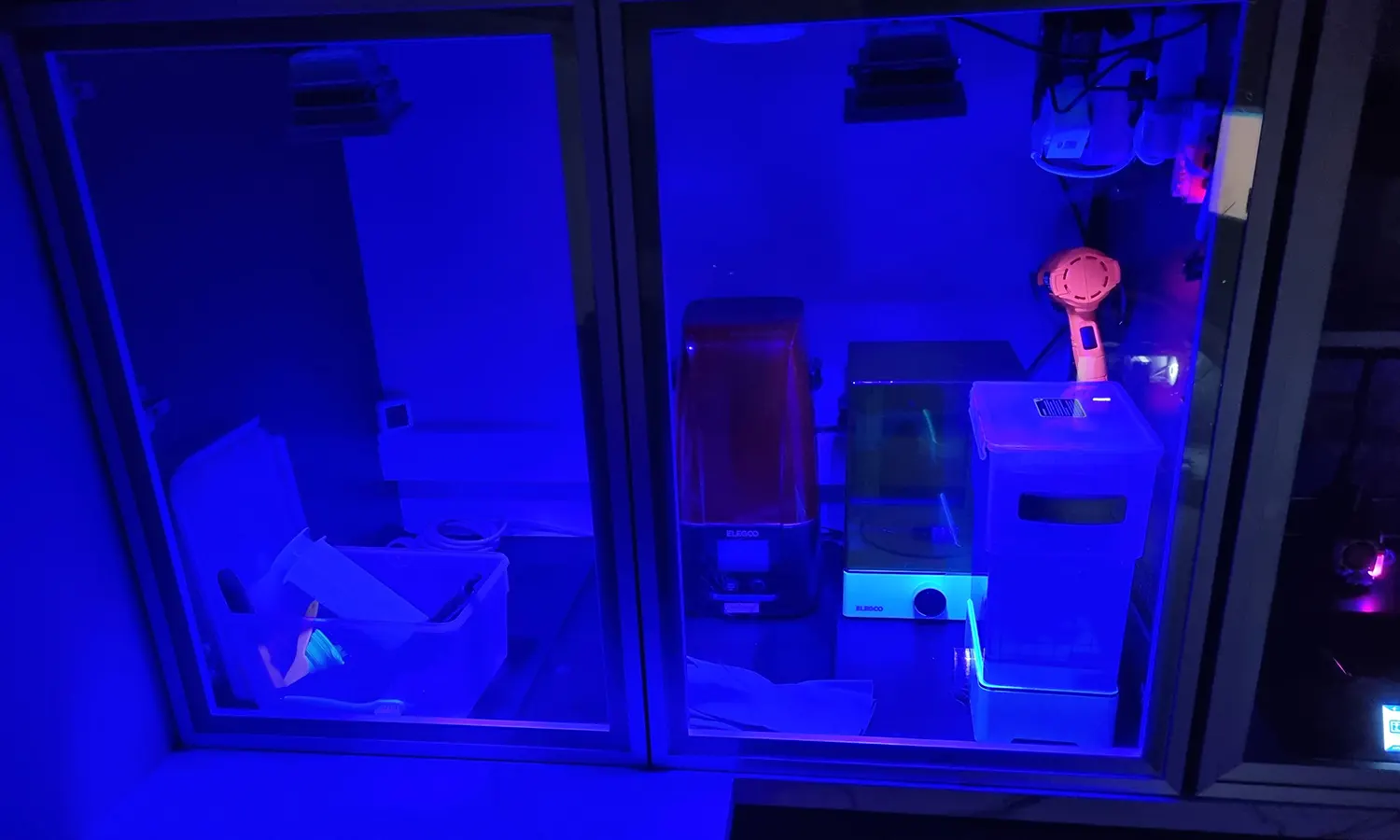

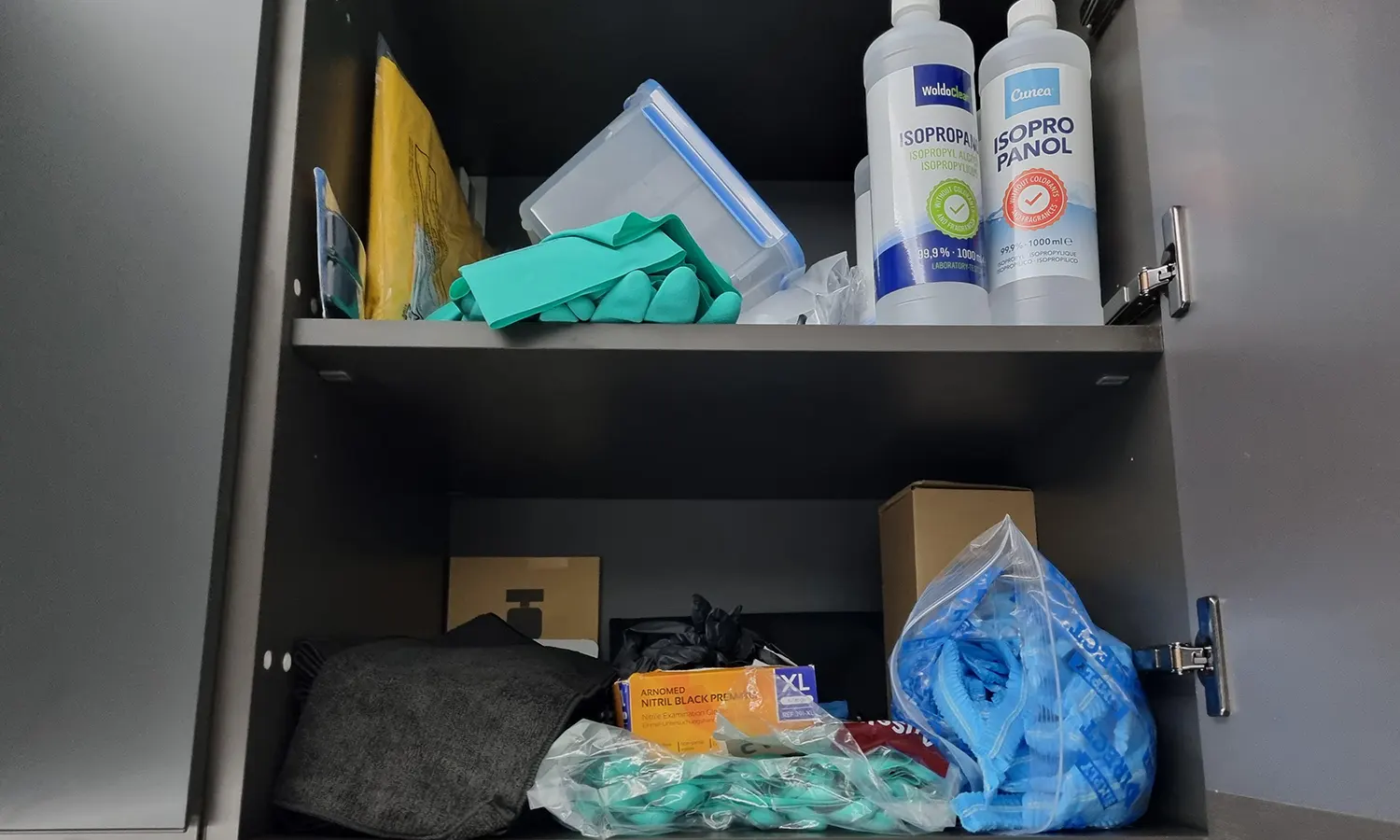

Community Resin Setups

Submit your awesome 3D printer setup!

These are excellent community examples to provide some inspiration in creating your setup.

Email entries to [email protected]. We prefer the images to be landscape and at minimum 1,500x900 px. Try to capture the essence of your setup in a single photo. If you have an exceptional setup that needs multiple photos, we'll use multiple slots or create a small slideshow.

3D Printing Grow Tent Enclosures

Grow tents are ideal for both FDM and resin printers

The reasons why grow tents are widely used in resin printing is that they are affordable, easy to set up, and sturdy.

A 30 x 18 x 36 inch grow tent retails between $70 to $100. This size can fit a smaller resin printer, a heater, cleaning equipment, and resin bottles. The grow tent can always been turned onto its side to fit a FDM printer.

3D Printing Ventilation Fans and Duct

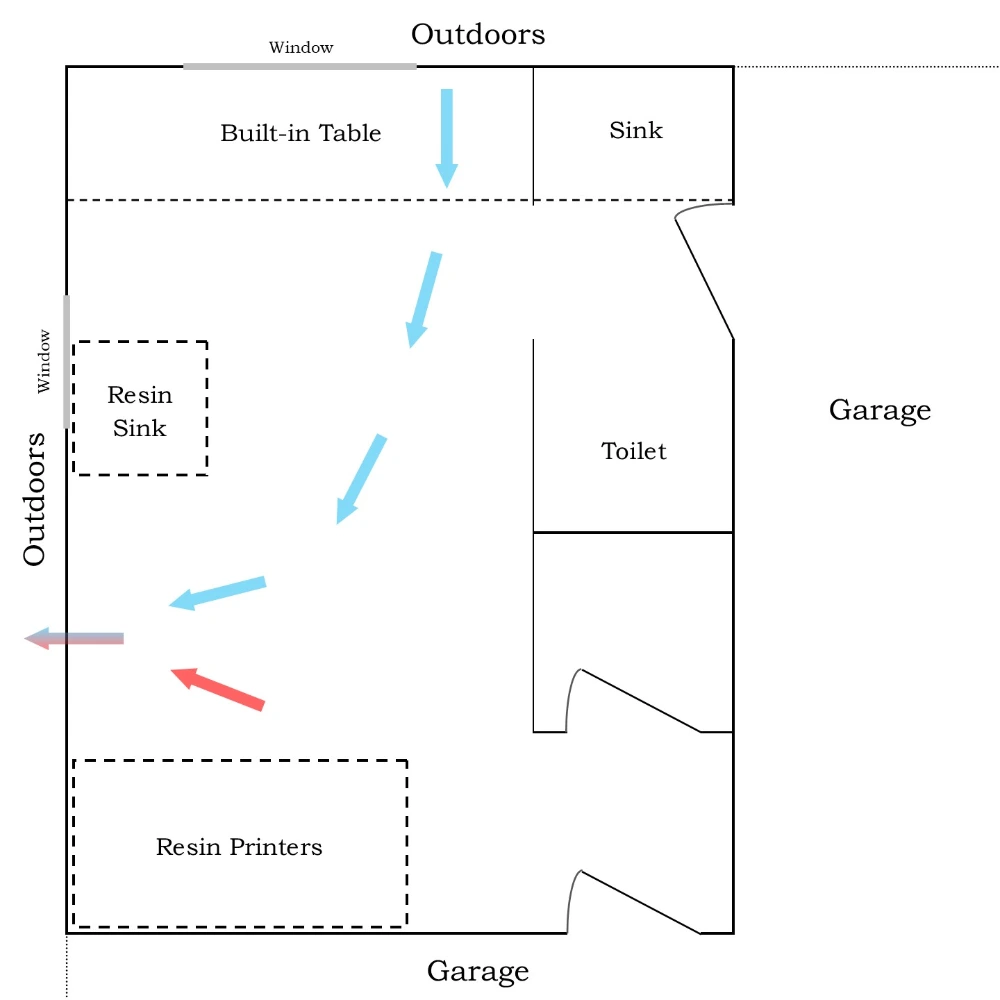

How a 3D printing room can use ventilation

This is a detached room of a house that is used for FDM and resin printers. Clean air is let in through one window, and contaminated air is exhausted out of a duct vent in the wall.

To learn more about how this room was setup, visit our guide on preparing for resin printing.

3D Printing Ventilation Simulations

Visualize particle behavior and airflow patterns in different situations

The following simulations are intended to provide a comparison between common ventilation scenarios for 3D printers. The animations represent the behavior of the particulates and VOCs that are suspended by airflow.

The color gradient (blue=good to red=bad) showcases the concentration distribution. The exact concentrations present during printing are not represented.

No Ventilation - Worst Case Scenario

An indoor room with no ventilation allows for the particulate and/or VOC concentration to increase. Resin that off-gasses will eventually spread to the rest of your home.

The mixture remains suspended by free convection that is powered by heat from electronics, sunlight, and artificial light.

Close Off HVAC Grilles In The Room

With any setup, the household HVAC system can push or pull contaminated air into the rest of the home. Consider sealing these grilles off in order to gain more control over your ventilation. However, if the room only has a HVAC exhaust and not a return grille, then the central heat may prove useful during the winter.

Garage Or Indoor Open-Air Ventilation

We define open-air ventilation as the exchange of indoor and outdoor air without the use of an enclosure, fume hood, or similar system. The downside to this solution is that contaminated air will mix within the room.

The use of a fan sealed against the window, such as an inline fan attached to a window adapter, creates negative pressure in the room. This ensures that indoor air is exhausted and contaminated air should not intrude into the rest of the house. Keep in mind that the HVAC can create positive pressure instead.

A box fan or open window is viable for the short-term, but these let in outdoor air that mix and can push contaminated air into the remainder of the house.

Enclosure Ventilation

This is the ideal indoor solution for ventilation since the contaminated air is contained and instantly vented outdoors. This setup will prevent contaminated air intruding into the house, and it will minimize the impact on the air temperature and electricity use of the residence.

Miscellaneous Simulations

If the printer is on a balcony or patio with a 5 mph wind

While not always practical, placing the printer outside allows for particles to be swiftly carried away by a light wind.

The goal of ventilation is to attempt to reach this behavior while the printer is indoors.

If a garage or room has a box fan in a window

Perhaps the cheapest garage or indoor solution, putting a box fan in the window will move a lot of air but will gradually expose the entire room to the external temperature.

In a garage, this could work when it is warm outside, but the cool winter air can result in print failures. A small heater will be needed in this case.

The simulated box fan is rated at 1,800 CFM and ≈0.10 inH2O.

If another window or door is cracked open

Slightly opening a window allows for air to enter the room, ensuring that there are no stale pockets of air. The static pressure experienced by the fan is lowered, thereby increasing the flow rate.

This case will be common for most rooms due to air leaking in through cracks, ducts, and under doors.

If another window or door is fully open

Fully opening a window or door maximizes the circulation and ventilation of the air-particle mixture.

Remember that this showcases the particle behavior and not the concentration.

If a grow tent is used to vent the resin fumes

This is an ideal solution for ventilation since the particles are contained and there is minimal impact on the air temperature of the residence.

The simulated enclosure is a grow tent that lets air in through the zipper and small cracks. The ventilation is provided by a 120 mm fan with a meager 40 CFM and 0.11 inH2O.

Smaller fans prevent excess heated/cooled indoor air from being lost during printing. However, when the enclosure is opened, the small fan is not able to extract the fumes to the extent that a tube-axial (inline) fan could.

3D Printing Air Filtration

Use filtration as a secondary defense to emissions

Installing ventilation should always be the primary focus, with filtration acting as a secondary defense. In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filter media is replaced regularly.

For resin printers, even if ventilation is installed, you may feel more comfortable with the extra layer of defense provided by a fume extractor or air cleaner.

For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive and their enclosures will not be vented.

Particulates can be efficiently removed with MERV 13-16 or HEPA filters. HEPA filters are not always the best option since they often have a lower flow rate compared to a MERV filter, but they perform well for fume extraction.

The efficient removal of VOCs will require a bed of activated carbon granules or pellets. Impregnated foam is not recommended since it is not as efficient nor as long-lasting as granules.

The capture efficiency of professional/industrial activated carbon systems can be 92-98%, but smaller units with a carbon thickness of 1-2 inches have an efficiency of 40-60%.

The capture efficiency of carbon will vary depending on the chemicals, impregnation, thickness, temperature, air speed, and etc. The efficiency will decrease when the carbon surpasses a saturation threshold dependent on the thickness of its mass transfer zone.

We recommend visiting our 3D Printing Air Quality Roundup article to get the latest information on safety.

Resin Printer Fume Mitigation

These small air cleaners are designed to be placed inside the acrylic cover of a resin printer. These small air cleaners only provide mitigation and should not be solely relied upon.

The units only use activated carbon so they be able to capture an estimated 40-60% of fumes until they become saturated. Particulates will not be captured to any meaningful extent.

The P Mini air cleaner's files are free to download, it uses a blower fan with a higher static pressure, the extra battery capacity gives hours of additional use, and the thick carbon bed will have a longer life and higher capture efficiency.

4D Filtration - P Mini

DIY

Battery: 5,000 mAh

Carbon: 50 g

Dimensions: 53x53x133 mm

Anycubic - AirPure

$30

Battery: 2,000 mAh

Carbon: 13.6 g

Dimensions: 46x46x115 mm

Elegoo - Mini Air Purifier

$30

Battery: 2,000 mAh

Carbon: 13.6 g

Dimensions: 44x44x107 mm

3D Printing Fume Extractors

Fume extractors are designed to remove the majority of containments from the air leaving an enclosure.

The Promethean air cleaner is offered as an affordable alternative that can be hooked up using duct, be inside an enclosure, or next to the printer. Additionally, the high flow rate allows it to act similar to a normal air cleaner.

The BOFA fume extractors utilize HEPA media, have a thicker carbon bed, and are more quiet - the downside is the price bump. Fume extractors are ideal for resin and FDM.

4D Filtration - Promethean

DIY

MERV Filter: $15

Activated Carbon: $25

Airflow: 11-27 cfm

Noise: 41-68 dB

Protection: Particulates & VOCs

MERV or HEPA & Carbon Granules

BOFA - Print Pro 2

$770

Combo Filter: $260

Airflow: 26.5 cfm

Noise: <44 dB @ "typical"

Protection: Particulates & VOCs

HEPA & Carbon Granules

BOFA - Print Pro 3

$1,200

Combo Filter: $260

Airflow: 88 cfm

Noise: <57 dB @ "typical"

Protection: Particulates & VOCs

HEPA & Carbon Granules

3D Printer Ventilation FAQ

The easiest way to vent 3D printer fumes is to enclose the printer, connect duct to a window adapter, and use an exhaust fan.

The safest 3D printer to use in an apartment is FDM with PLA. Engineering filament like ABS or resin printers should be in a separate room and vented out a window.

If you live in student housing, we recommend against getting a resin printer or using engineering filament. If complaints are made, at the very least, you could be forced to remove the printer. College libraries and city makerspaces should have the printers needed for your projects.

The garage is one of the best places for a 3D printer. Placing the printer in a garage will prevent fumes from entering your home.

The 3D printer can be enclosed to contain heat and prevent debris from damaging the printer. The garage can be vented by opening a window or the door after a print finishes.

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.